Category: Difference between cement & concrete

Cement and Concrete: A Basic Foundation

What are cement and concrete – is there a difference?

Cement is the basic ingredient of concrete, so while these terms are often used interchangeably they are two unique products. Concrete is made when cement is mixed with water, sand and rock.

How is cement made?

Cement is a manufactured product created by a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients.

Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand and iron ore.

These ingredients, when heated at high temperatures form a rock-like substance that is ground into the fine powder that we commonly think of as cement.

Throughout the process, cement plant laboratories check each step with chemical and physical tests to ensure the finished product complies with all industry specifications.

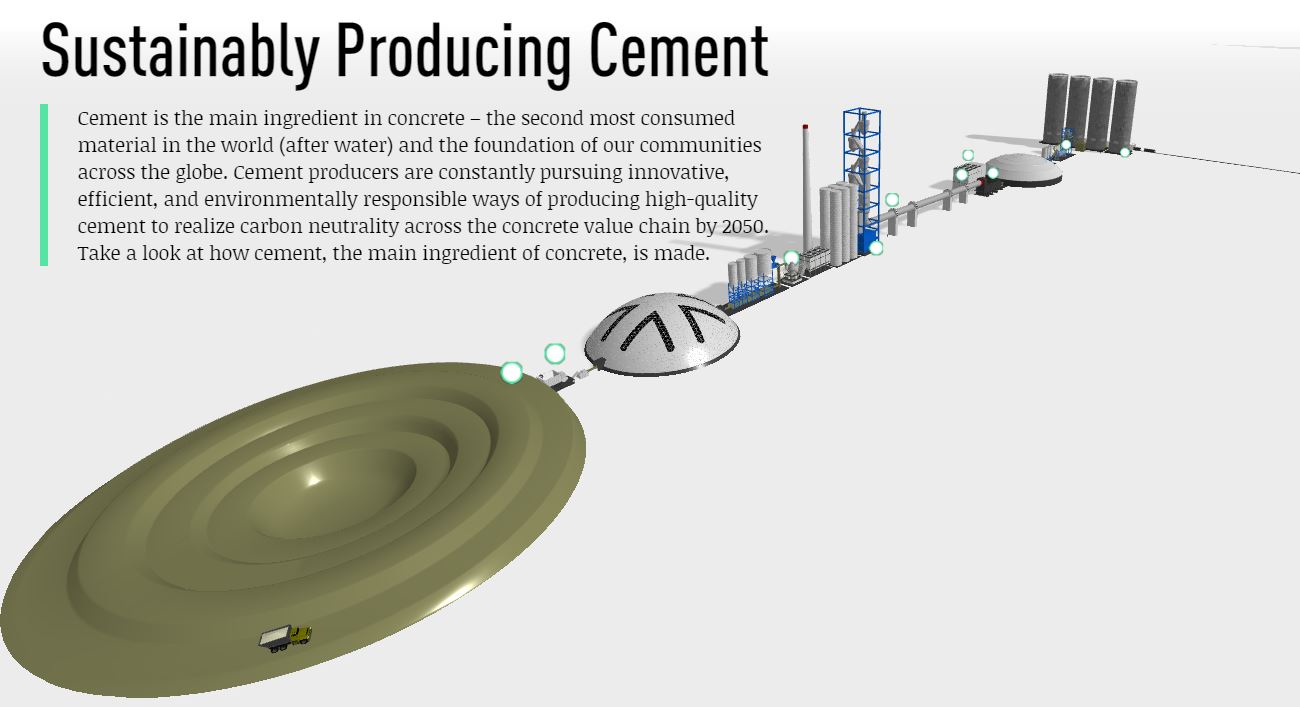

How cement is made more sustainably

Cement producers have a history of reducing carbon emissions and are in constant pursuit of finding ever more innovative and efficient ways of producing the high-quality cement our nation needs for things like homes, highways, hospitals and infrastructure. In fact, cement companies are working toward carbon neutrality across the concrete value chain.

Here’s a look at some of the actions already underway to making cement production more sustainable:

How is concrete made?

Concrete is a mixture of a paste (formed from cement and water) and rocks (smaller aggregates). Cement and water are combined to form a paste that is then mixed with aggregates and coats each stone and sand particle. Through a process called hydration, the cement and water harden and bind the smaller aggregates into a rock-like mass. This hardening process continues for years meaning that concrete gets stronger as it gets older.

While this may seem simple, the key to achieving strong, durable concrete is careful proportioning and mixing of ingredients. Typically, a mix is about 10 to 15% cement, 60 to 75% aggregate and 15 to 20% water. Small air bubbles in many concrete mixes may also take up another 5 to 8%.

There are four different forms of concrete, each with unique properties and applications:

Ready-mix concrete is the most common form and accounts for nearly three-fourths of all concrete. This is the concrete that you see in trucks with revolving drums, often at construction sites.

Ready-mix concrete is the most common form and accounts for nearly three-fourths of all concrete. This is the concrete that you see in trucks with revolving drums, often at construction sites. Precast concrete is shaped in a factory as it requires tight quality control. Precast products range from concrete bricks and paving stones to structural construction components and wall panels. These units can be molded into a wealth of shapes, configurations, colors and textures to serve an infinite spectrum of building applications and architectural needs.

Precast concrete is shaped in a factory as it requires tight quality control. Precast products range from concrete bricks and paving stones to structural construction components and wall panels. These units can be molded into a wealth of shapes, configurations, colors and textures to serve an infinite spectrum of building applications and architectural needs. Cement-based materials represent products that defy the label of “concrete,” yet share many of its qualities. Conventional materials in this category include mortar, grout and terrazzo. Soil-cement and roller-compacted concrete—“cousins” of concrete—are used for pavements and dams.

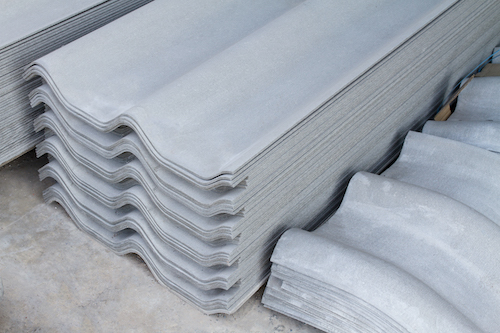

Cement-based materials represent products that defy the label of “concrete,” yet share many of its qualities. Conventional materials in this category include mortar, grout and terrazzo. Soil-cement and roller-compacted concrete—“cousins” of concrete—are used for pavements and dams. A new generation of advanced products incorporates fibers and special aggregate to create roofing tiles, shake shingles, lap siding and countertops.

A new generation of advanced products incorporates fibers and special aggregate to create roofing tiles, shake shingles, lap siding and countertops.