Mike Ireland

President and CEO, PCA

When I joined the Portland Cement Association, it wasn’t for the fame – the cement and concrete industry does not often find itself in the limelight. Rather, I was drawn to the innovative and hardworking people that make up PCA’s member companies and to be a part of our nation’s literal (though overlooked) foundation. Cement and concrete are in almost every structure, providing strength, durability and resiliency not found in many other places; this industry quietly enables us to go about our daily lives.

We now find ourselves thrust into the mainstream narrative with cement and concrete manufacturers at the heart of the Biden Administration’s $1 trillion infrastructure plan. With the realities of climate change accelerating, the U.S. needs that infrastructure to withstand the natural disasters we increasingly face. At the same time, society is demanding action on emissions, and I believe that we have a responsibility to answer that charge. The spotlight has found us, and our industry is grabbing this opportunity to accelerate change with both hands – we can come together to reduce our carbon footprint while increasing production and delivering sustainable infrastructure.

A year ago, on behalf of the U.S. cement industry, PCA released a Roadmap to Carbon Neutrality – an ambitious plan outlining actions and opportunities across the entire cement-concrete-construction value chain. We’ve seen progress on this journey – and we need every stakeholder, from the smallest construction company to the federal government, to work with us on continuing to further this goal.

The Roadmap advocates for the increased use of low-carbon cement, such as portland limestone cement, and there are now 44 state Departments of Transportation that accept this mix, which results in 10% less carbon. In California alone, using PLC has the potential to reduce carbon dioxide emissions by 28,000 tons a year — the equivalent of removing more than 6,000 cars from the road.

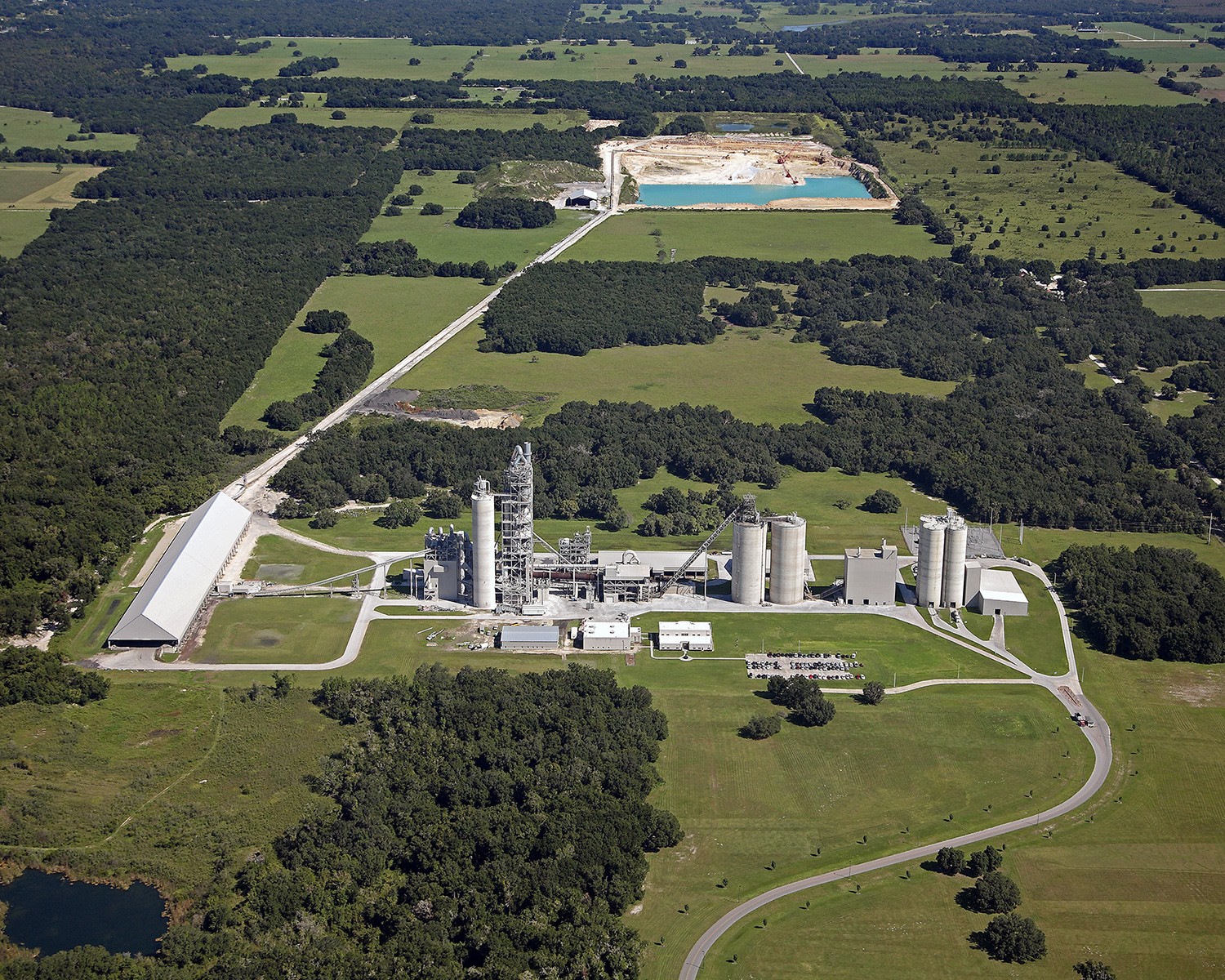

Multiple cement manufacturers in the U.S., with support from the Department of Energy, have begun pilot projects around emerging technologies that capture carbon before it is emitted and reusing it for another purpose or storing it – commonly referred to as carbon capture, utilization, and storage (CCUS).

I want to recognize the work that has been done, but there are so many more opportunities to unlock in the Roadmap.

This plan considers the full lifecycle of cement and concrete – no material, structure or technology can be considered in isolation, and PCA looks to the wider construction industry as partners on this journey. The Roadmap identifies opportunities to lower emissions at each step of concrete construction, from updating building codes to more thoughtfully designing a structure for its intended use, to shifting to zero emissions fleets to deliver the materials, to measuring and accounting for the carbon that’s absorbed within concrete over its lifetime.

We are proud of the developments to-date, and we applaud all our members and partners who have taken the first steps in creating and implementing the solutions needed to bring us toward a more sustainable future.

With your help, let’s do more. Read the full Roadmap to Carbon Neutrality and you reach out to us at customerservice@cement.org to learn more about the cement and concrete industry’s path toward a sustainable, resilient future.