A new ‘greener’ cement supports sustainability efforts

Concrete is ubiquitous in our daily lives and a key part of building sustainable, resilient communities. The cement and concrete industry is committed to research and innovation to evolve and provide solutions to continue to improve upon these essential materials, helping to create a more environmentally responsible future.

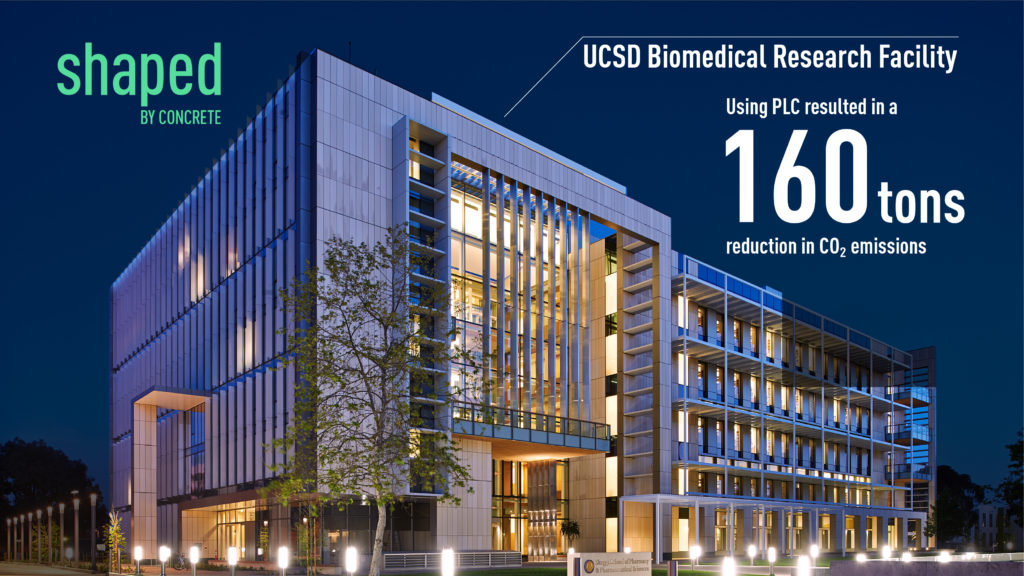

Portland-limestone cement (PLC) is a type of cement that has been common internationally for decades but is relatively new to North America. PLC’s main benefit is a lower carbon footprint, reducing carbon dioxide emissions during production by 10% on average. In fact, by shifting production to PLC, manufacturers have already reduced carbon dioxide emissions by more than 325,000 metric tons in the U.S. from 2012-2018, equivalent to carbon stored in over 400,000 acres of forest.

Concrete is the most used building material in the world and a key part of U.S. infrastructure because it is durable; resilient; does not rust, rot or burn; and can withstand powerful storms. Now, it is also greener.

What are the benefits?

How does it work?

PLC is produced in a way that is very similar to traditional portland cement, the only difference being more limestone is used during the mixing process, resulting in a reduction in carbon dioxide intensity.

PLC has undergone extensive testing and research in the U.S. and other countries to ensure its durability and resiliency. PLC also is simple to switch to as it is a 1:1 replacement for traditional portland cement. This allows users to continue their standard operations with minimal disruption and change. The decrease in carbon emissions makes PLC a more sustainable, yet equally resilient and dependable option as a building material.

As we continue to rely on concrete to support our thriving cities, the cement and concrete industry is ensuring that the second most used materials in the world continues to evolve and become more sustainable. Because of the frequency that concrete is used, even small changes to its formulation, making it greener, can have a dramatic impact on emissions.

To learn more about PLC, visit greenercement.com.

For more information about the sustainability properties of concrete, visit Sustainability Practices in the Cement and Concrete Industry.

For more information about the impact of cement and concrete across their full lifecycle, visit Concrete Creates Sustainable and Environmentally Responsible Infrastructure.