Month: March 2021

A ‘Greener’ Cement Supporting Sustainability and Reducing Carbon Footprint

Filiberto Ruiz

President and Chief Executive Officer, Votorantim Cimentos North America

Vice Chairman, PCA Board of Directors

Concrete is ubiquitous in our daily lives. As the world’s most-used man-made material, it is an essential part of infrastructure improvements and new construction throughout North America. Concrete is durable; resilient; doesn’t rust, rot, or burn; and can withstand powerful storms. Now, it is also greener.

Portland-limestone cement (PLC) is a type of cement that has been common internationally for decades but is still relatively new to North America. PLC’s main benefit is a lower carbon footprint, with CO2 emissions reduced during production by 10% on average. In fact, by shifting production to PLC, manufacturers have already reduced CO2 emissions by more than 325,000 metric tons in the U.S. from 2012-2018 — equivalent to the amount of CO2 stored in over 400,000 acres of forest — without sacrificing the material’s physical properties needed for their projects.

Here are a few examples how PLC is already helping reduce CO2 emissions in the U.S.:

- Using PLC contributed to a 50% lower carbon footprint for Mississippi State University’s Davis Wade Stadium.

- Using PLC to build new bridge decks, the Tennessee Department of Transportation saved about 50 lbs. of CO2 for each cubic yard of concrete – the equivalent of the energy emissions from charging 2,892 smartphones.

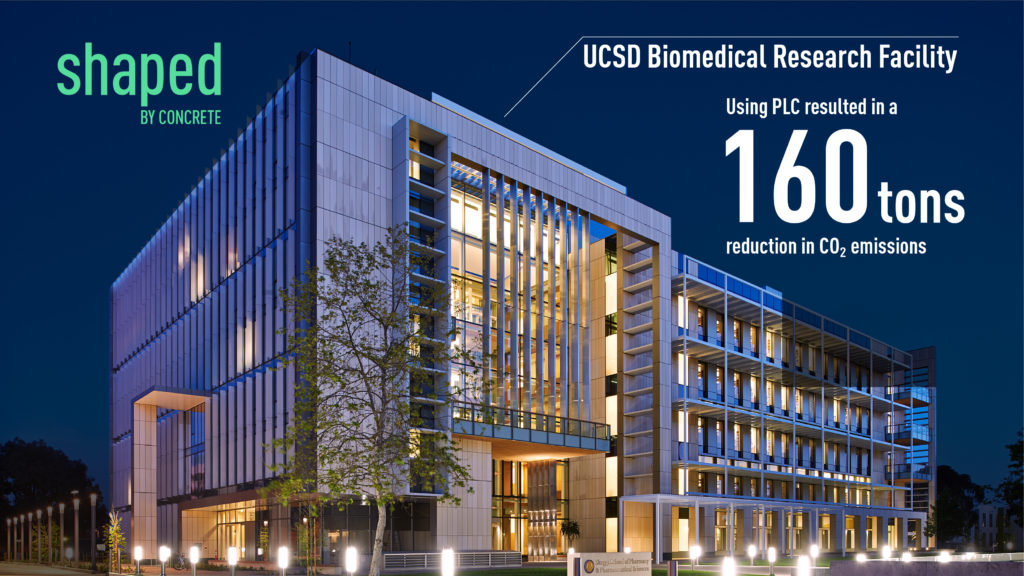

- Using PLC to construct the University of California, San Diego biomedical research facility resulted in a 160-ton reduction in CO2 emissions, which is equal to the energy emissions from burning 176,298 lbs of coal.

- The ongoing construction of the Drexel University Academic Tower is using PLC and saving about 370 tons of CO2 emissions – equivalent to energy emissions from 41,634 gallons of gasoline consumed.

These examples prove that as we continue to rely on concrete to support our thriving cities and rural areas, the cement and concrete industry is working diligently to ensure the building materials we need are becoming more sustainable. Because of the scale at which concrete is used, even small changes to its formulation to make it greener can have a dramatic positive impact on emissions.

PLC is produced in a way that is very similar to traditional portland cement, the only difference being more limestone is used during the mixing process, resulting in a reduction in CO2 intensity.

PLC has undergone extensive testing and research in the United States and other countries to ensure its durability and resiliency. Builders and designers can expect the same strength with minimal disruption and change to their projects. The decrease in CO2 emissions makes PLC a more sustainable, yet equally resilient and dependable option as a building material.

The cement and concrete industry is committed to continuing research and innovation to provide greener solutions to improve upon these essential materials, helping to create more sustainable communities and an environmentally responsible future for our planet.

To learn more specifics about portland-limestone cement, visit greenercement.com. And, to Learn more about the cement and concrete industry’s commitment to sustainability visit shapedbyconcrete.com.

Reducing Carbon Footprint with PLC

A new ‘greener’ cement supports sustainability efforts

Concrete is ubiquitous in our daily lives and a key part of building sustainable, resilient communities. The cement and concrete industry is committed to research and innovation to evolve and provide solutions to continue to improve upon these essential materials, helping to create a more environmentally responsible future.

Portland-limestone cement (PLC) is a type of cement that has been common internationally for decades but is relatively new to North America. PLC’s main benefit is a lower carbon footprint, reducing carbon dioxide emissions during production by 10% on average. In fact, by shifting production to PLC, manufacturers have already reduced carbon dioxide emissions by more than 325,000 metric tons in the U.S. from 2012-2018, equivalent to carbon stored in over 400,000 acres of forest.

Concrete is the most used building material in the world and a key part of U.S. infrastructure because it is durable; resilient; does not rust, rot or burn; and can withstand powerful storms. Now, it is also greener.

What are the benefits?

How does it work?

PLC is produced in a way that is very similar to traditional portland cement, the only difference being more limestone is used during the mixing process, resulting in a reduction in carbon dioxide intensity.

PLC has undergone extensive testing and research in the U.S. and other countries to ensure its durability and resiliency. PLC also is simple to switch to as it is a 1:1 replacement for traditional portland cement. This allows users to continue their standard operations with minimal disruption and change. The decrease in carbon emissions makes PLC a more sustainable, yet equally resilient and dependable option as a building material.

As we continue to rely on concrete to support our thriving cities, the cement and concrete industry is ensuring that the second most used materials in the world continues to evolve and become more sustainable. Because of the frequency that concrete is used, even small changes to its formulation, making it greener, can have a dramatic impact on emissions.

To learn more about PLC, visit greenercement.com.

For more information about the sustainability properties of concrete, visit Sustainability Practices in the Cement and Concrete Industry.

For more information about the impact of cement and concrete across their full lifecycle, visit Concrete Creates Sustainable and Environmentally Responsible Infrastructure.