Category: Enhancing sustainability

Reducing Vehicle Emissions and Improving Fuel Efficiency

The role of concrete in improving the efficiency of our roads

Fuel consumption and related emissions from vehicles depend on a number of factors like the size of the vehicle and the type of engine, but most drivers might be surprised to learn that the quality of the roads we drive on also impacts the amount of fuel our vehicles use. On roads where surface conditions are poor, vehicles consume more fuel beyond what is actually needed to move, which leads to excess fuel consumption and emissions.

Damaged city roads can increase the amount of fuel used – and the associated greenhouse gas emissions – by as much as 15%.[1]

Concrete offers the most fuel-efficient pavement option. Because of its rigidity, concrete pavement can enhance the fuel efficiency of vehicles that travel on concrete pavement roads when compared to other pavements, and due to its durability, it requires less frequent maintenance and doesn’t wear down as quickly as other pavements.

If concrete pavements were used by the entire U.S. road system, fuel consumption is estimated to decrease by 3% nationwide, which corresponds to a reduction of approximately 46.5 million metric tons of greenhouse gas emissions.[2]

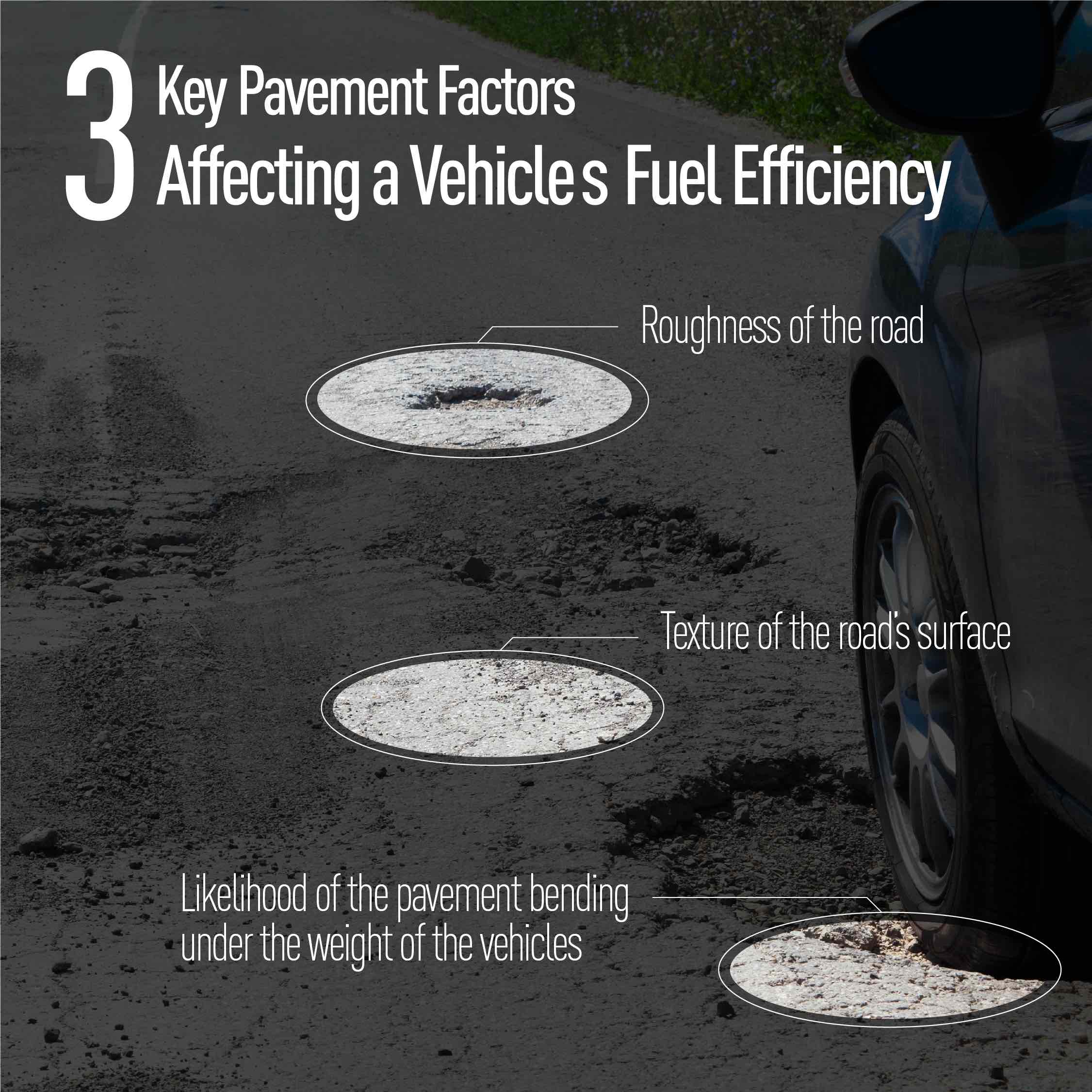

Three key pavement factors affect a vehicle’s fuel efficiency

- The roughness of the road, commonly seen and felt as cracks and potholes

- The texture of the road’s surface, which impacts traction when wet

- The likelihood that the pavement will bend under the weight of the vehicles

As these three factors create additional, unnecessary friction for vehicles and reduce their fuel efficiency, optimizing pavement conditions can reduce carbon dioxide emissions. There are two strategies for creating more optimal pavement conditions: build stiffer pavements and maintain smoother pavements – and concrete pavement offers both.

Facts and stats

Studies across the U.S. have shown the impact of poor pavements:

- An analysis of approximately 50,000 miles of highway in California found that over a five-year period 1 billion gallons of excess fuel was used.

- A study of 5,000 miles of Virginia’s interstate highways found that excessive fuel consumption resulted in 1 million tons of carbon dioxide over a seven-year period.

- When looking at 40-ton trucks (used for freight and trucking), decreasing the impacts of deflection through stiffer roads can lead to a fuel savings of up to 4%, which translates to 2 million tons of carbon dioxide.

For additional information, please visit the MIT Concrete Sustainability Hub.

For more information about the sustainability properties of concrete, visit Sustainability Practices in the Cement and Concrete Industry.

Sustainability Practices in the Cement and Concrete Industry

The role of concrete in building a low-carbon, circular economy

Every year, the U.S. uses approximately 260 million cubic yards of concrete to build highways, bridges, runways, water and sewage pipes, buildings and homes, dams, sidewalks and driveways. As the second most used material on the planet after water, the U.S. cement industry is committed to minimizing emissions, waste, energy consumption and the use of virgin raw materials.

Cement is becoming more energy efficient – and the industry continues to progress on efficiency

The cement industry began to address climate change in the mid-1990s—one of the first industries to do so.

- The industry has reduced its use of traditional fossil fuels by over 15%.

- In 2020, The Environmental Protection Agency ENERGY STAR® Program recognized 95 manufacturing facilities in the U.S. as ENERGY STAR® certified for operating in the top 25 percent of efficiency performance in their respective industry sectors. The cement industry represented 13 of those facilities.

- According to 2019 ENERGY STAR® data, cement plants have reduced energy-related carbon emissions by 1.5 million metric tons, annually.

- Since 1990 manufacturers have reduced carbon intensity by 11.9% along with general energy consumption while actually increasing production.

Leading the use and development of alternative fuels

The cement industry is a leader in sustainable material and fuel use. In fact, the cement industry expands the circular economy by diverting waste materials from landfills and uses them for fuel or incorporates them as valuable additives.

- Burning alternative fuels in cement kilns like scrap tires, packaging, plastics and solvents conserves valuable fossil fuels while safely destroying wastes that would otherwise be deposited in landfills.

- Elements like aluminum, iron and silica that are used to produce clinker can come from industrial byproducts of the coal and steel industry, creating better and more sustainable uses for these byproducts.

- The Construction Materials Recycling Association estimates that about 140 million tons of concrete are recycled each year in the U.S., reducing the environmental impact of construction projects.

Lowering emissions in buildings and our urban environments

The durability, resiliency and insulating qualities of cement-related products lower our environmental footprint as a society. Considered across their full lifecycle, cement and concrete building materials are also valuable contributors to a low-carbon circular economy.

- According to the MIT Concrete Sustainability Hub, by adopting the latest building codes and concrete mixes, emissions from U.S. office buildings could decrease by 12%.

- Concrete does not rust, rot or burn, saving energy and resources needed to replace or repair damaged buildings and infrastructure.

- Concrete makes urban areas cooler as its lighter color reflects more sunlight than other, darker materials.

- Because of its durability, concrete structures will not require additional carbon release to produce additional materials used for repairs.

- Over time, concrete actually absorbs carbon dioxide from the ambient air, returning a portion of emissions from the cement manufacturing process to the building itself.

- In fact, for all of the concrete produced in the U.S. between 1990 and 2018, more than 300 million metric tons of carbon dioxide will be adsorbed and sequestered by concrete over its service life.

Sustaining our transportation network

A well-functioning transportation network is the backbone of the U.S. economy and essential for U.S. businesses to compete globally and provide the best value to American consumers.

- Because of its rigidity, concrete pavement can enhance the fuel efficiency of vehicles that travel on concrete pavement roads when compared to other pavements.

- Concrete structures, including pavement, are long-lived – concrete pavement has an average service life of 30-50 years.

- Concrete pavement is less susceptible to damage from heavy vehicles and requires little to no maintenance throughout its service life.

- Concrete pavements do not require lengthy lane closures, with roads able to reopen within as little as six hours. This reduces time-in-traffic auto emissions.

For more information about how concrete is the best choice for sustainable pavements, visit Reducing Vehicle Emissions and Improving Fuel Efficiency.